Research

Unveiling effects of Zr alloying on structure and properties of nanocrystalline Cu-Zr films

Advanced electrical characterization of thin films

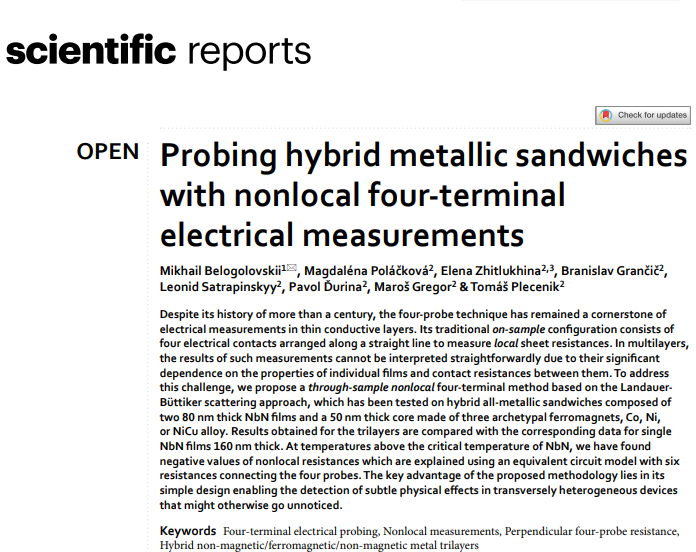

The four-probe technique is a cornerstone of electrical measurements in thin conductive layers. In a recent study by Prof. Mikhail Belogolovskii and colleagues from Comenius University Bratislava performed nonlocal through-sample four-terminal electrical measurements of a multilayer heterostructures, composed of a 50 nm thick ferromagnetic metal layer (NiCu, Ni, or Co) embedded between two 80 nm thick non-magnetic NbN layers.

Due to the complex nature of multilayer structures, the interpretation of the resistance measurements is not straightforward. To overcome this challenge, the team developed a six-resistor model based on the Landauer-Buttiker scattering approach that provides information about charge transport across interfaces and within individual layers. The transversal four-terminal electrical measurements successfully revealed charge transport features hidden inside the layered structures.

The electrical transport measurements were carried out using a Physical Properties Measurement System (PPMS), which allows precise control of magnetic field intensity and orientation. Combined with a wide temperature range - from room temperature down to milikelvins - this steup allows for in-depth electrical characterisation of thin films and multilayer structures.

This approach - comprehensive analysis and modeling of physical properties - is part of the expertise we offer to partners seeking advanced insight into both the fundamental and applied aspects of their materials.

High-performance dielectric AlxTayOz thin films

Dielectric thin films are essential in microelectronics, capacitors, and energy storage systems. Their performance directly impacts the efficiency, reliability, and miniaturization of modern electronic devices. Our research provides a deeper understanding of how to fine-tune material properties through precise control of deposition parameters – especially oxygen flow and target composition.

Our experts and paper’s authors Richard Drevet, Pavel Souček, Pavel Mareš, Pavel Ondračka, Matej Fekete, Martin Dubau, and Petr Vašina focused on optimization of a dielectric thin films in recent paper „Influence of Oxygen Flow on the Structure, Chemical Composition, and Dielectric Strength of AlxTayOz Thin Films Deposited by Pulsed-DC Reactive Magnetron Sputtering“. This work was a collaboration between the Department of Plasma Physics and Technology, CEPLANT, Masaryk University, and HVM Plasma, Prague.

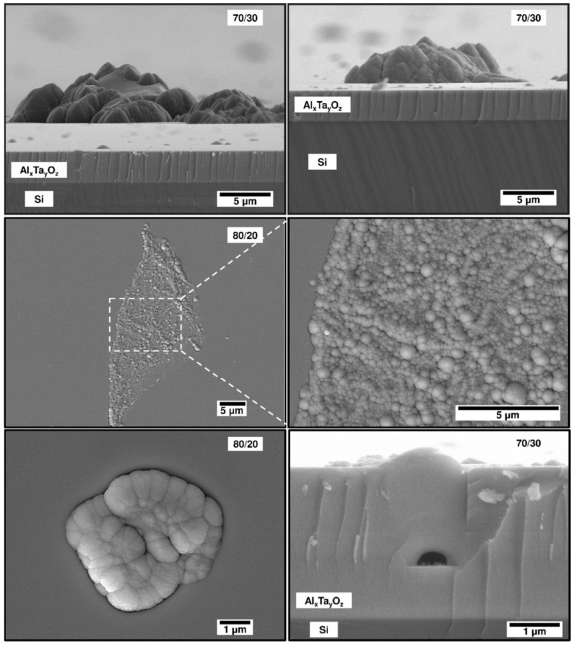

Among the key results: intermediate oxygen flow rates produced the highest dielectric strength, increased tantalum content helped mitigate target poisoning and arcing, and optimized deposition conditions resulted in dense, uniform, and poorly crystalline films with improved functional properties.

This approach —the morphological analysis and compositional and structural characterization of surfaces is part of the expertise we offer to partners seeking advanced insights to ensure the consistent and reliable performance and outcomes.

Novel and sustainable materials design strategy

Developing multifunctional, high-performance, and scalable thin-film materials remains a key challenge in surface engineering. This study demonstrates a novel and sustainable materials design strategy based on the use of only two metallic elements, Zr and Cu, combined in both low-temperature non-reactive and reactive magnetron sputtering processes using argon and nitrogen-containing atmospheres. This streamlined approach enables the formation of a variety of binary and ternary compounds with a broad spectrum of compositions and microstructures. The key innovation lies in the development of a hierarchical multilayer architecture that integrates elastic ZrCu thin-film metallic glass, hard nanocrystalline ZrN, and nanocomposite ZrN–Cu into a single coating system. This architecture results in a multifunctional material that combines high hardness, mechanical damage tolerance, and long-term antibacterial activity.

The study is the result of cooperation between Montanuniversität Leoben, University of West Bohemia in Pilsen and the Austrian Academy of Sciences.

Experience with diverse deposition technologies, design of deposition processes and coating architecture are all part of the expertise we offer to partners seeking advanced insight into thin-film materials and coating processing technologies.

From laboratory to industrial applications: Scaling Magnetron Sputtering

Magnetron sputtering is a well-established method for creating thin films. Still, the predominant public research is conducted on lab-scale setups, leaving a gap when translating the findings into real-world and industrial applications. Our experts and paper's authors Peter Klein, Jaroslav Hnilica, Vjačeslav Sochora, and Petr Vašina explore critical differences in deposition fluxes and ionisation of metals when scaling from lab to industrial systems. Their results reveal that in lab-scale DC sputtering, the number of metal ions is limited and often insufficient for optimal thin film formation. In contrast, industrial-scale systems demonstrated up to 30% of film-forming species present as ions, significantly enhancing the potential for high-quality coatings. Moreover, deposition rates in the industrial system were found to be ten times higher than those achieved in the lab setup.

Understanding and utilising these findings is essential, especially for industries relying on high-throughput, high-performance coatings. If you're working at the intersection of research and production, this kind of insight could reshape your approach to thin film processing. This approach — the diagnostics of deposition processes is part of the expertise we offer to partners seeking advanced insights to ensure the consistent and reliable performance and outcomes.

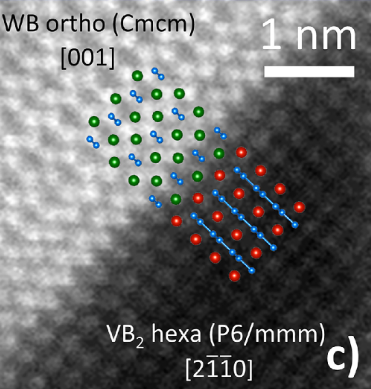

Prediction of heterostructural decomposition via density functional theory (DFT): when energetics drive structural transitions

Transition metal diborides show great potential for industrial applications. To tune their mechanical and electrical properties, we need detailed understanding of the structure. DFT calculations can help us with predictions, as well as explaining the observed structural phenomena. In this study on V1-ₓWₓB₂-Δ films, we used DFT to show that boron deficiency promotes a separation into hexagonal VB2 and orthorhombic WB regions observed by transmission electron microscopy. The DFT calculation further revealed that the decomposition is driven by different affinities of the binary V-B and W-B systems to boron vacancies.

This approach — based on first-principles modelling of structural stability — is part of the expertise we offer to partners seeking advanced material insights, design guidance, or predictive evaluation.